LKT Paper – Löhner, M.; Drummer, D., Journal of Polymers (Hindawi)

Accepted on November 1st 2016

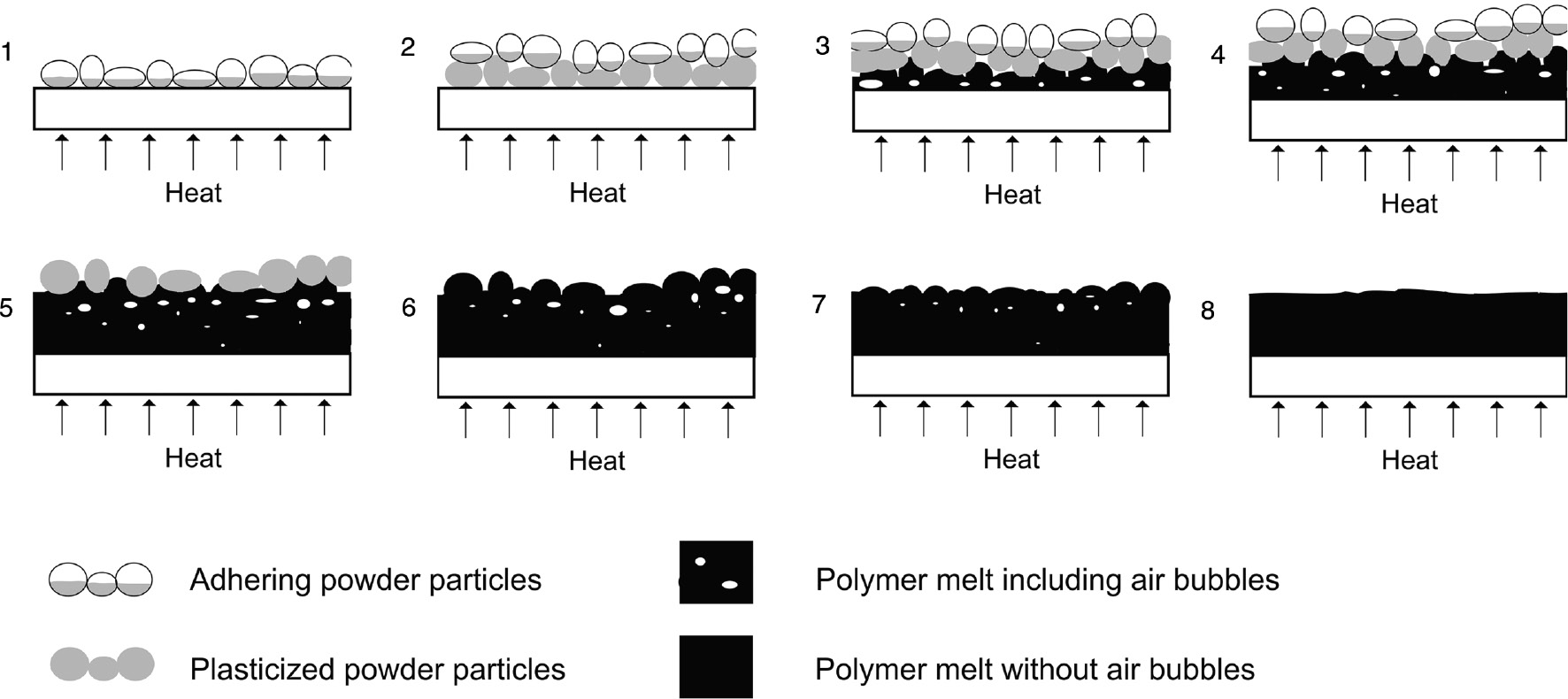

Abstract: Rotational molding is a plastic processing method that allows for the production of seamless, hollow parts. A defined shaping of the polymeric material only takes place on the outer surface where contact to the tooling is given. The inner surface forms by surface tension effects. By sequential adding of materials, complex multi-layer built-ups are possible. Besides pure, single materials, filled or multiphase systems can be processed as well. In this work, possibilities to generate bonding between supposedly incompatible materials by adding a mix-material interlayer are investigated. Interlock mechanisms on a micro-scale dimension occur and result in mechanical bonding between the used materials, Polyethylene (PE) and Thermoplastic Polyurethane (TPE-U). The bonding strength between the materials was investigated to reveal the correlations between processing parameters, resulting layer built-up, and bonding strength. The failure behavior was analyzed and inferences to the influence of the varied parameters were drawn.